Liyang pumped storage power station is located in Liyang city, Jiangsu province. The upper reservoir is located in the Wuyuanshan

work area of longtan forest farm, bordering Anhui province. The lower reservoir is located in Wu village, Tianmuhu lake town, next to Shahe reservoir. It is the largest pumped storage power station in Jiangsu province.

Construction

1 Structure

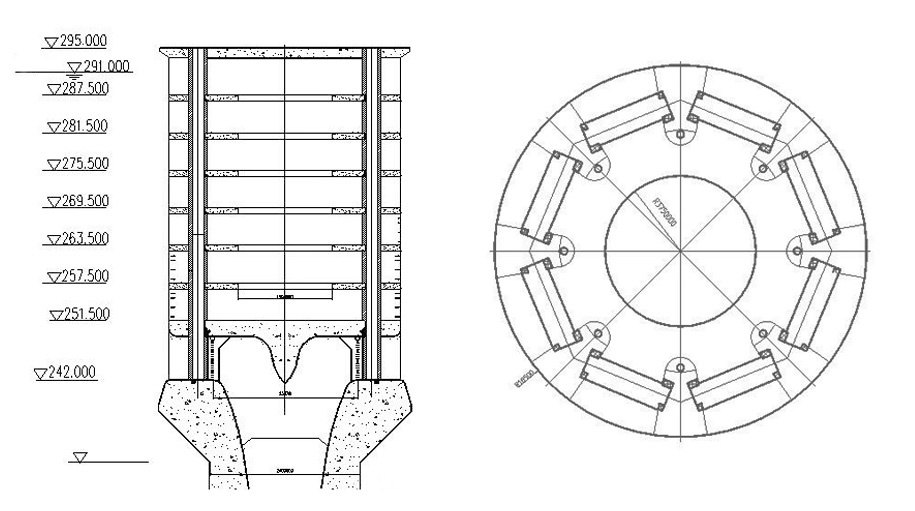

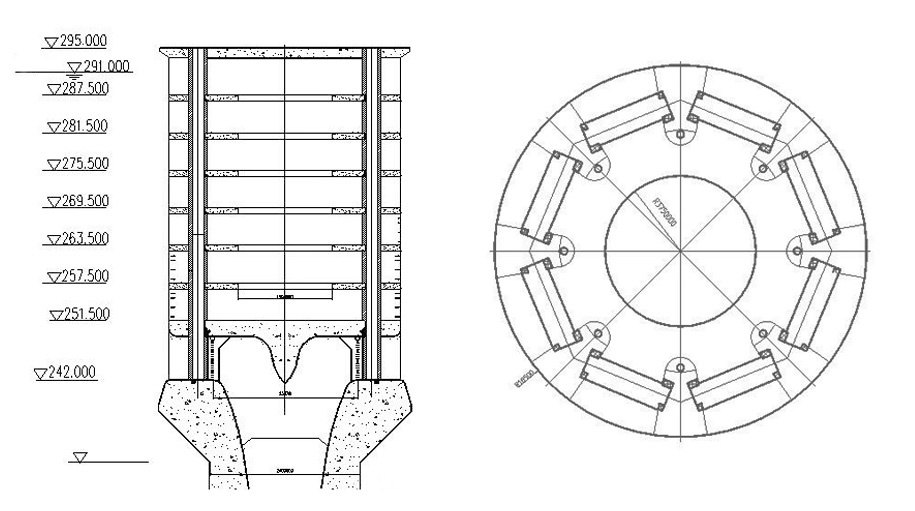

There are two water inlet and outlet in the upper reservoir. Tower high project is EL242 ~ EL295. The upper frame of the

tower body is mainly composed of 8 special-shaped columns and connecting plates, which are arranged along the central ring direction of the tower body. One connecting plate is arranged every 6 m high, and a gate groove is reserved in

the middle of the column and connecting plate. Inside the gate groove of the column body, vents with a diameter of 0.8 m are set. The connection plate is 1m thick, which is a circular ring structure with an outer diameter of 37m and

an inner diameter of 15 m. The project of EL295 on the top of the tower is a cover plate of 20m in diameter and 1.5 m in thickness. The cover plate is reserved with gate groove and vent.

2 Project difficulties

2.1 Loading of support. The combined line loading reached 56.47 kn/m, and the loading capacity of single standard reached 50.82

kn.

2.2 Thick plate. The minimum plate thickness of the standard layer is 1.0 m, and the maximum plate thickness of the top layer is

1.5 m.

2.3 Rectifier cone. The maximum thickness of the rectifying cone plate is 2.5 m, and concrete is poured in three times. It is

difficult to deal with the support of complex formwork with droplet load at the bottom.

3 Construction process

Construction process of supporting system: construction preparation--install base jack — erect the first span (standard and

ledger) — adjust the height and levelness of base jack — erect diagonal brace of first span — erect the second span (standard and ledger) —....erect the last span (standard and ledger) — erect U-head base jack

— Adjust the height of props — install beam — at last install formwork system.

3.1 Formwork system installation preparation

3.1.1 Wood is mainly used for the production and installation of various parts of abnormal wood formwork and formwork supporting

structure. The material, physical properties and strength of the wood should meet the design requirements. Wood formwork is made of high-quality plywood with a thickness of 18 mm and steel plate with a thickness of 12 mm. The wood

beam should be straight without bending, no twist, no decay, no holes, no worm eyes, no significant knot.

3.1.2 Design, production and installation of the processed special-shaped formwork shall ensure that the formwork structure has

sufficient strength and stiffness, can withstand the lateral pressure and vibration force of the concrete pouring and vibration, and firmly maintain the original sample, no displacement, no deformation, to prevent displacement and

ensure that the external dimensions of the concrete structure are accurate.

3.1.3 Steel formwork should be brand new or turnover of the use of a few times as far as possible, the surface of the formwork

should be smooth, tight joints, no leakage of slurry, to ensure the quality of the concrete surface.

3.2 Quality control of formwork

3.2.1 The formwork and its supporting system have sufficient loading capacity, stiffness and stability, and can reliably bear the

weight of poured concrete and construction load, etc.

3.2.2 Formwork joints shall be tight without leakage of slurry, and the width shall not be more than 2 mm. Before pouring

concrete should be watered and wet, but there should be no water in the formwork.

3.2.3 The surface of the formwork should be cleaned, and evenly brush the release agent, no leakage phenomenon.

3.2.4 Before pouring concrete, the debris in the formwork should be cleaned.

3.2.5 The allowable deviation of formwork installation shall meet the relevant requirements of the code for acceptance of

construction quality of concrete structure engineering.

3.2.6 The embedded parts, reserved holes and reserved holes fixed on the formwork shall not be omitted, and the installation

shall be firm, and the deviation shall meet the relevant requirements of the code for acceptance of construction quality of concrete structure engineering.

During the construction period of the project, Rapid scaffolding team has won high praise from customers with excellent product

quality and rich construction experience.